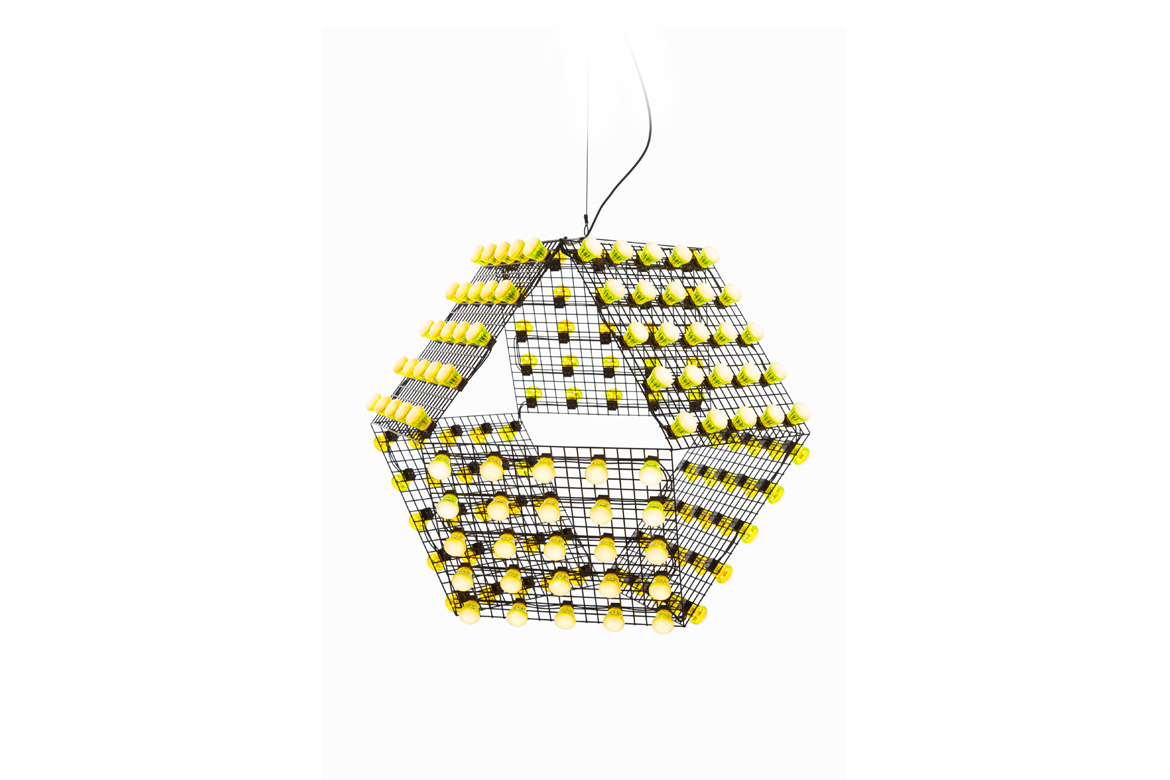

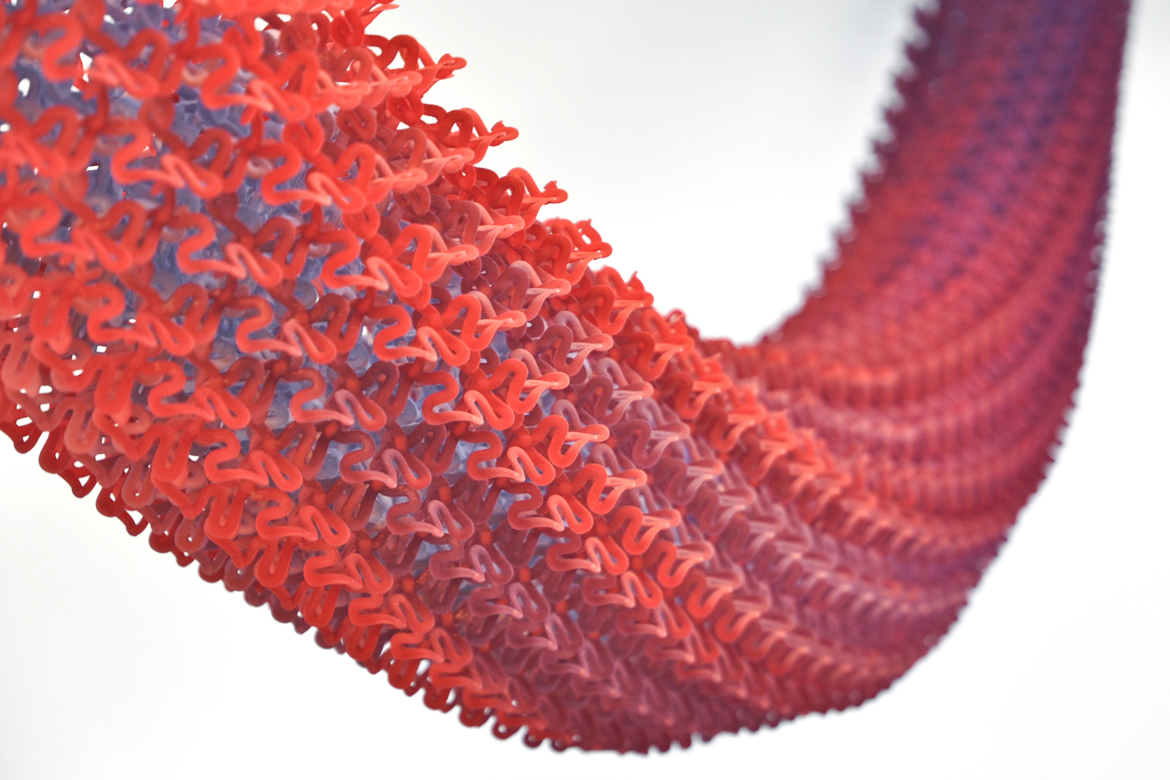

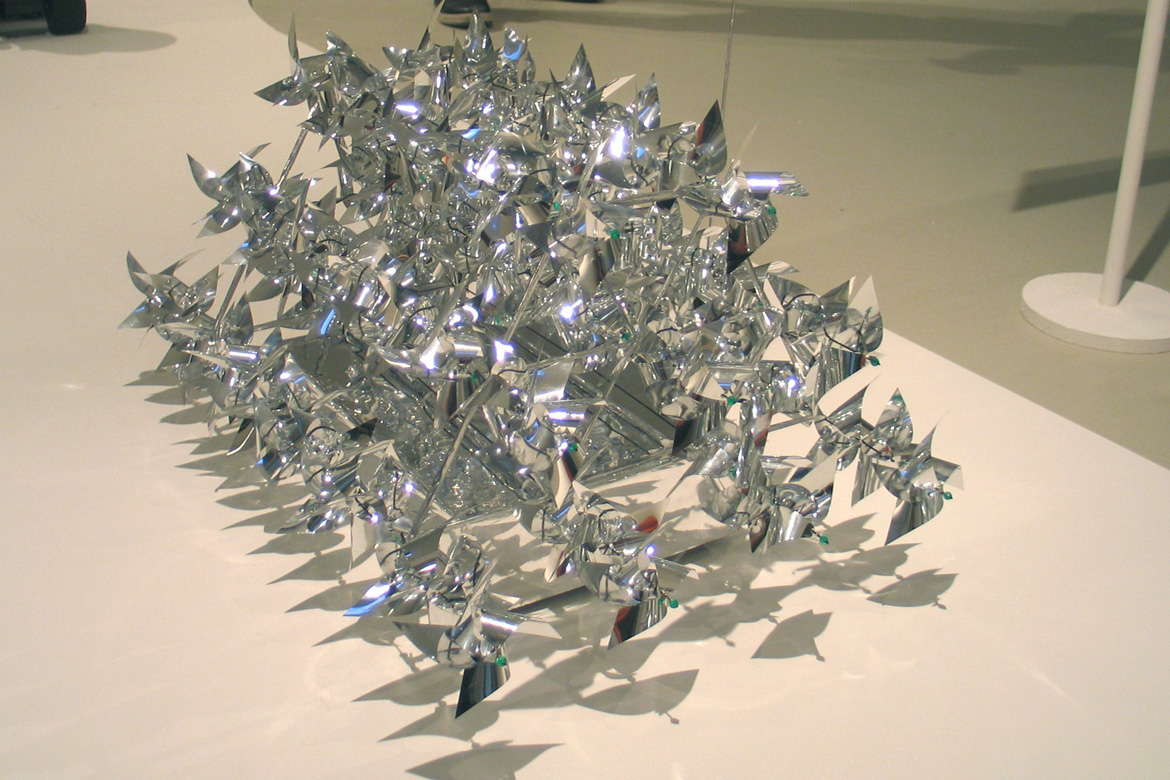

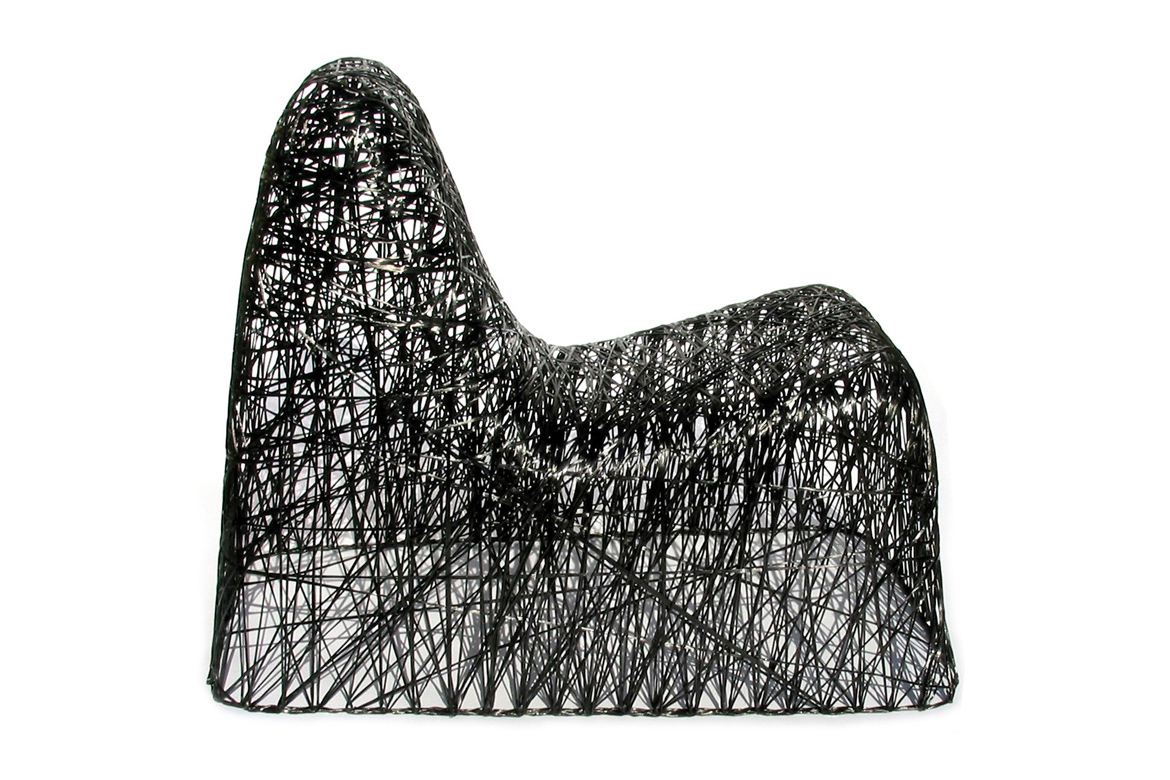

The Nylon garland is one of the things I made for a project organized by the Design Academy Eindhoven and TNO Eindhoven. Investigating the laser-sintering process (one of the many rapid prototyping techniques around these days) it struck me that although everything seems possible in this technique, certain things are more possible than others. Just like in wood and metal there are dos and don’ts. Laser sintering is a process that builds up a product in very thin layers. The layers can be 0.15 mm thin and are still quite strong. To be a bit stronger though, the connection between one layer and another should be 2.0x 2.0.mm. Although the technique is getting cheaper, anything that comes out of the machine is still quite expensive. I tried to take the Nylon to the max and created a small structure that could expand in size. Just to get as much volume possible for your money. The result was a pile of curly-shaped layers connected at various points. In fact it looks a lot like a paper garland, just a lot thinner and yes, a bit pricier. The garland was colored by dip dying the folded structure in different positions making the colors mix and fade. I hope to find a slightly more useful application for this beauty. Suggestions are welcome…